What Does EWM REACT Offer Us?

In September, EWM started to announce their new welding process called "REACT." Frankly, I held off until now because I wanted to see more of what was being shared and discussed on social media, rather than just relying on the information from their website. Let me give you a quick summary.

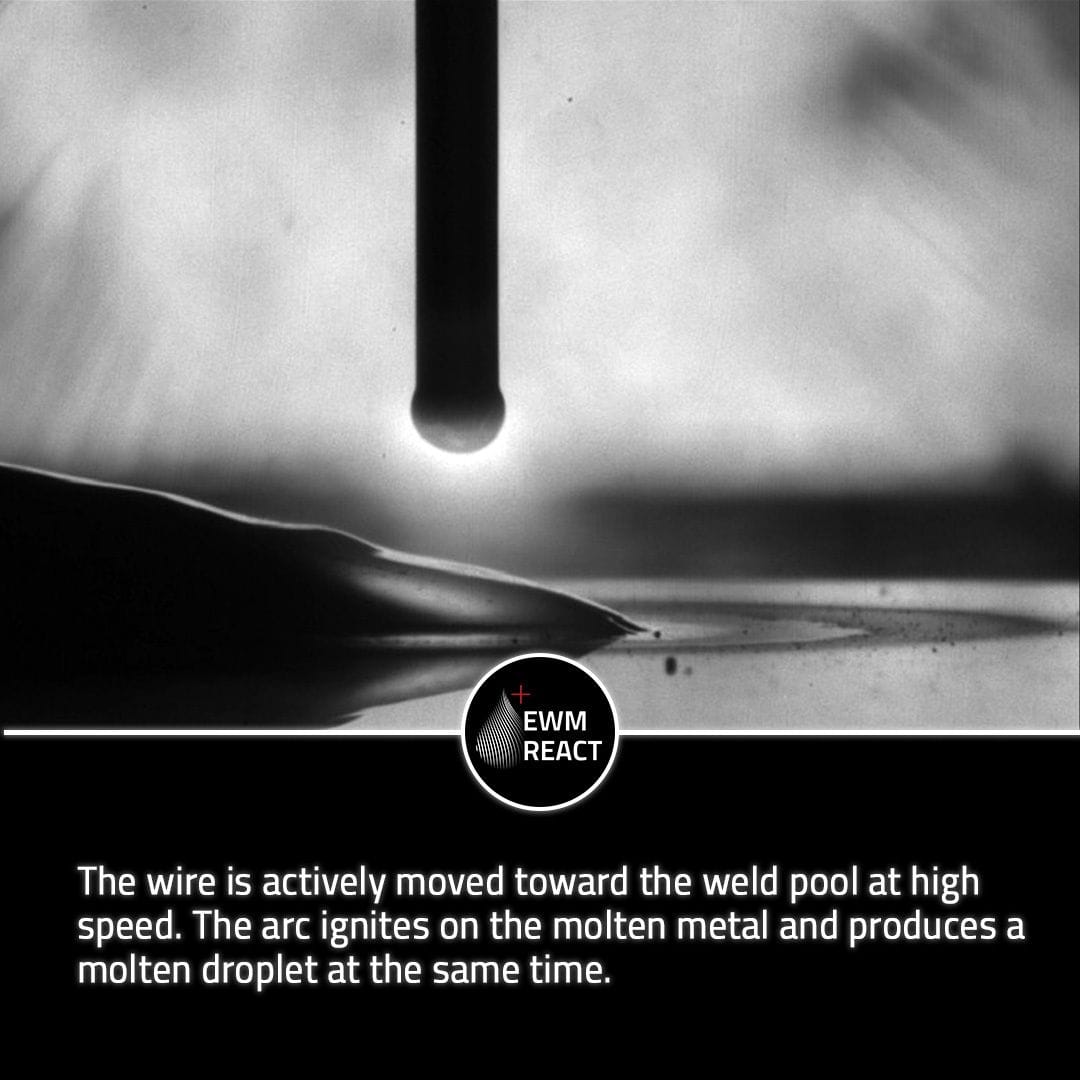

Here's how they define the word; REversing Actively Controlled Transfer. They say REACT combines the advantages of an energy-reduced, digitally controlled short arc with dynamic forward and reverse wire movement. They promise that this ensures maximum process stability and outstanding welding quality.

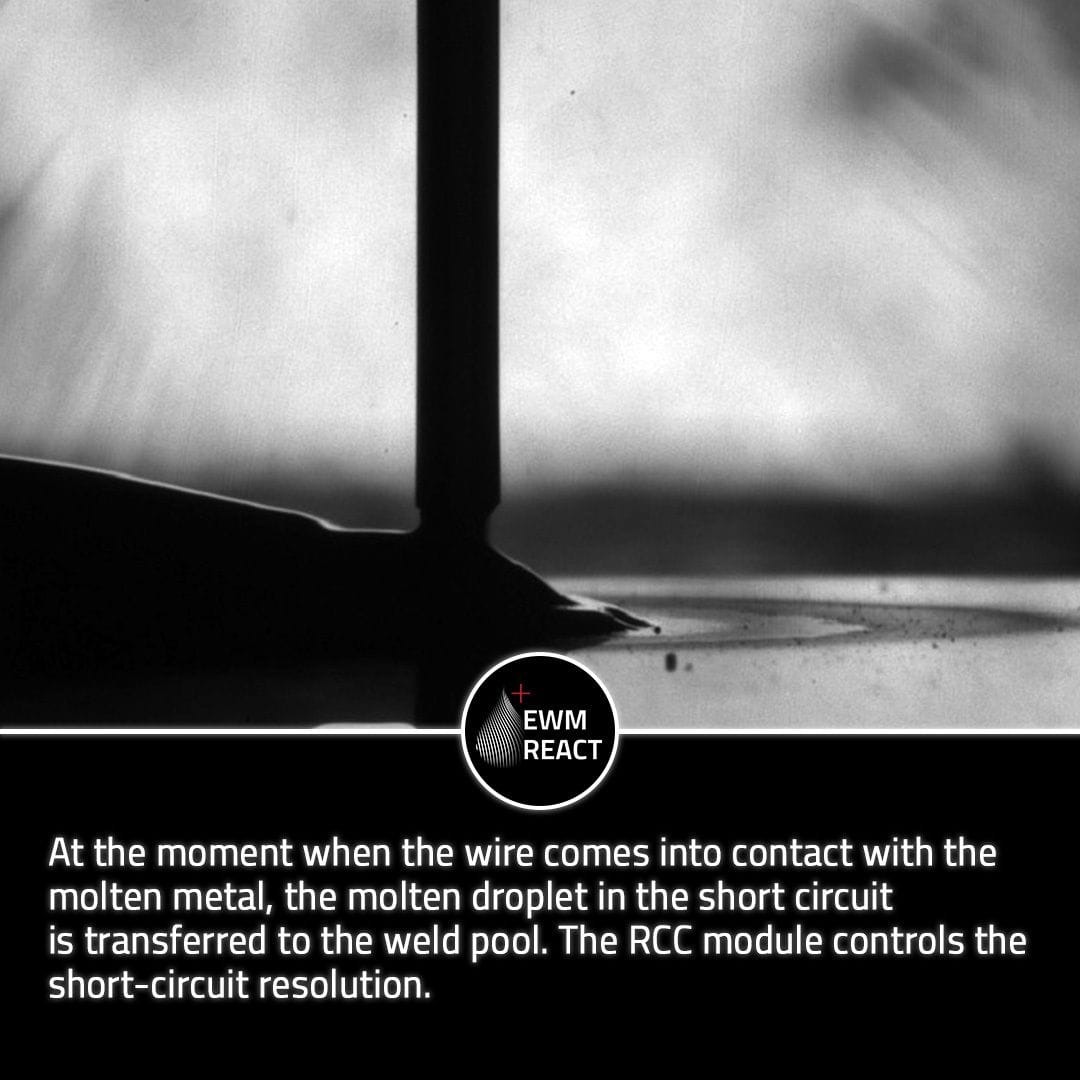

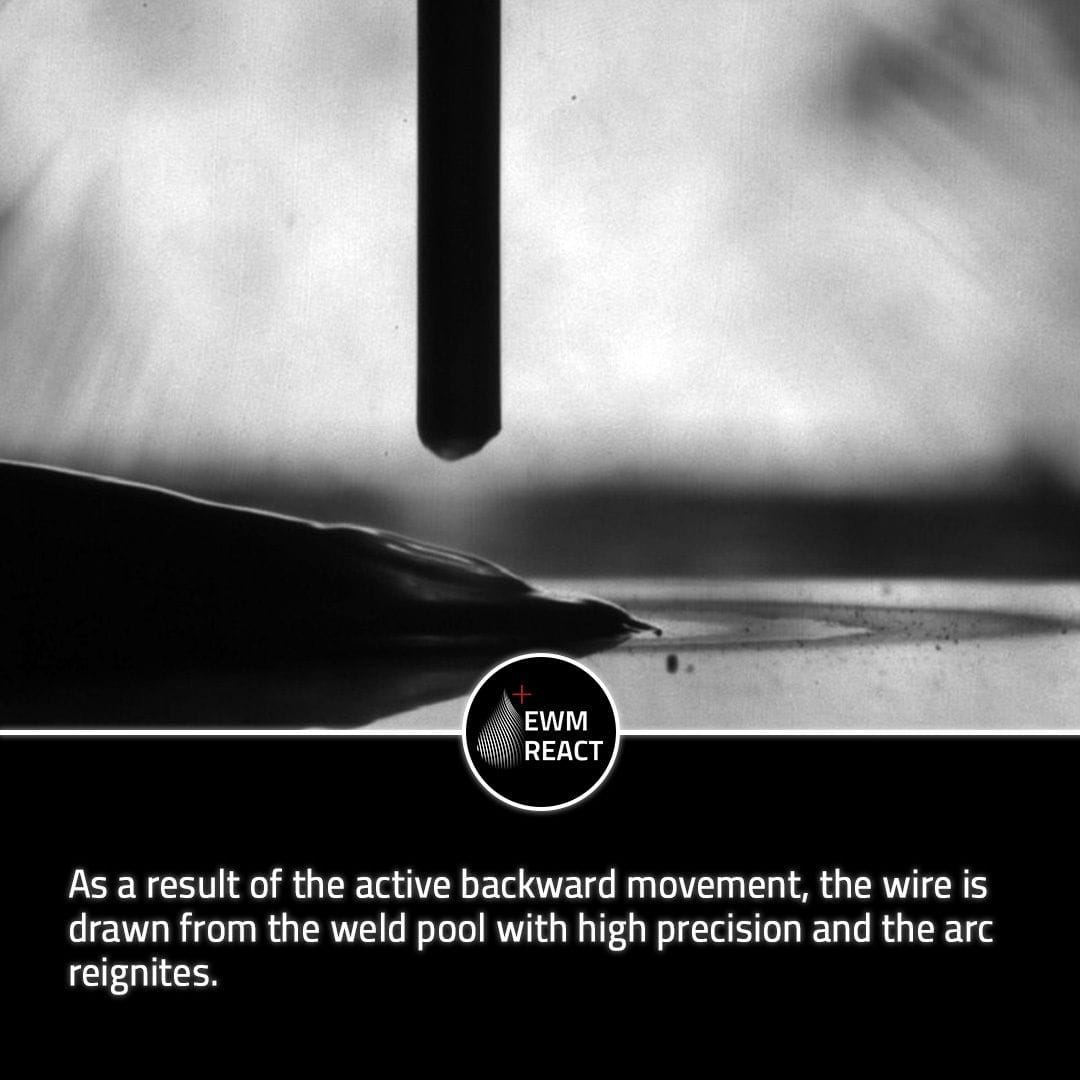

Short circuits are recognised immediately and the reversing wire movement supports droplet detachment. The wire moves forward, the short circuit occurs and the wire is actively retracted (push/pull movement). This increases the range of the short arc and a higher deposition rate is possible at very high welding speeds with lower heat input.

As a result of RCC (Rapid Current Control) module, they have achieved rapid current reduction, and when we add the controlled forward and backward movement of the wire, they state that it is possible to achieve almost spatter-free results. In addition to all of this, the low heat input allows for easy avoidance of distortion.

I wish I could show you more detailed application videos, but this is what we have for now. I think we can dive into a more in-depth analysis as we come across more media in the coming days.

Here is the LINK if you want to take a look at their website and brochure.

Discussion