UK Firm Wins Deepwater Weld Inspection Contract in Brazil

TSC Subsea, a UK-based specialist in remote subsea inspections, has secured a new multi-year contract to deliver phased array ultrasonic testing (PAUT) on circumferential welds in Brazil. The scope covers both flowline and riser welds at depths reaching 3,000 meters—conditions that demand reliable, high-performance inspection technology. The contract runs from 2025 to 2027 and includes continuous delivery of services across a broad range of subsea assets.

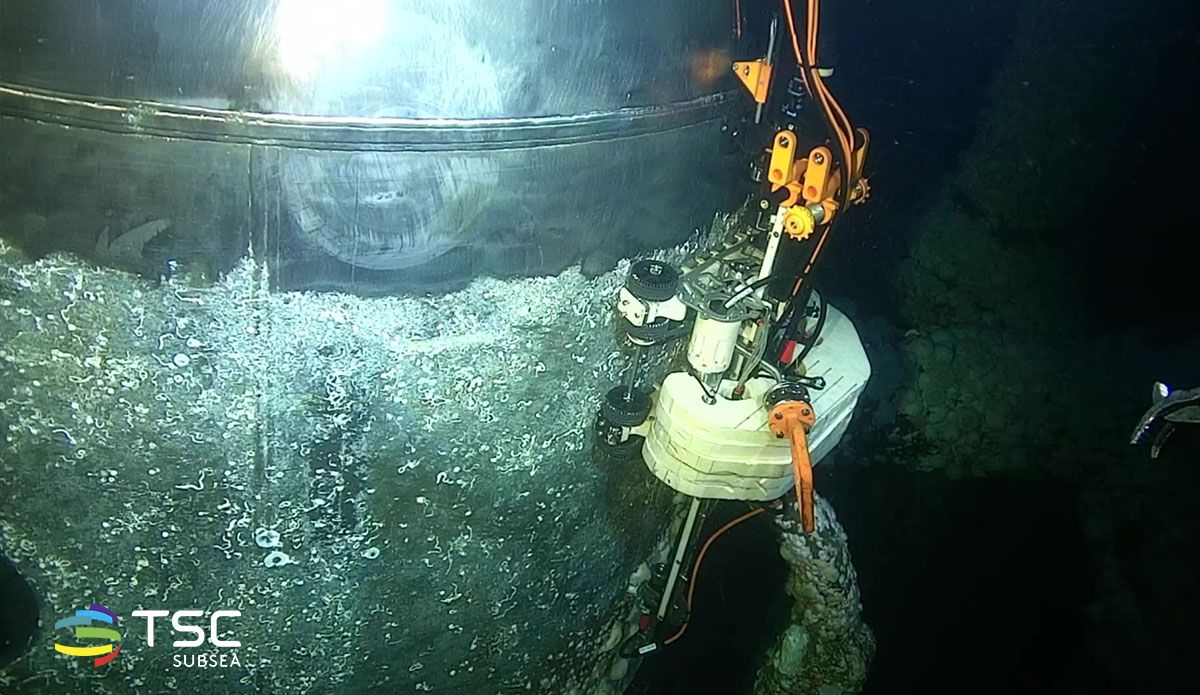

The inspection work will be carried out using TSC’s adapted SPA (Subsea Phased Array) technology, integrated with robotic systems engineered for ultra-deepwater environments. This same PAUT technology has already proven its accuracy and defect detection capability in topside applications, and its adaptation to deepwater use demonstrates a strong evolution of NDT (non-destructive testing) tools in extreme conditions. The qualification phase involved rigorous trials, including pressure chamber tests and inspections on coated test pipes embedded with known defects.

TSC Subsea emphasizes that their approach enables consistent, repeatable results—critical in subsea integrity management. With growing infrastructure complexity in offshore environments, the demand for precise weld inspection is rising, particularly for assets located in deep and ultra-deepwater. This contract signals not only confidence in the company’s robotic and NDT capabilities but also highlights the continuing role of advanced welding inspection in supporting the safe and sustainable development of offshore energy infrastructure.

Discussion