The Schaeffler Diagram: A Welder’s Roadmap to Success

Hey there, fellow welding enthusiasts! Ever found yourself scratching your head over which stainless steel filler metal to use or worried about unwanted phases popping up in your welds? Today, let's chat about the Schaeffler diagram—a handy tool that's been a game-changer in our industry.

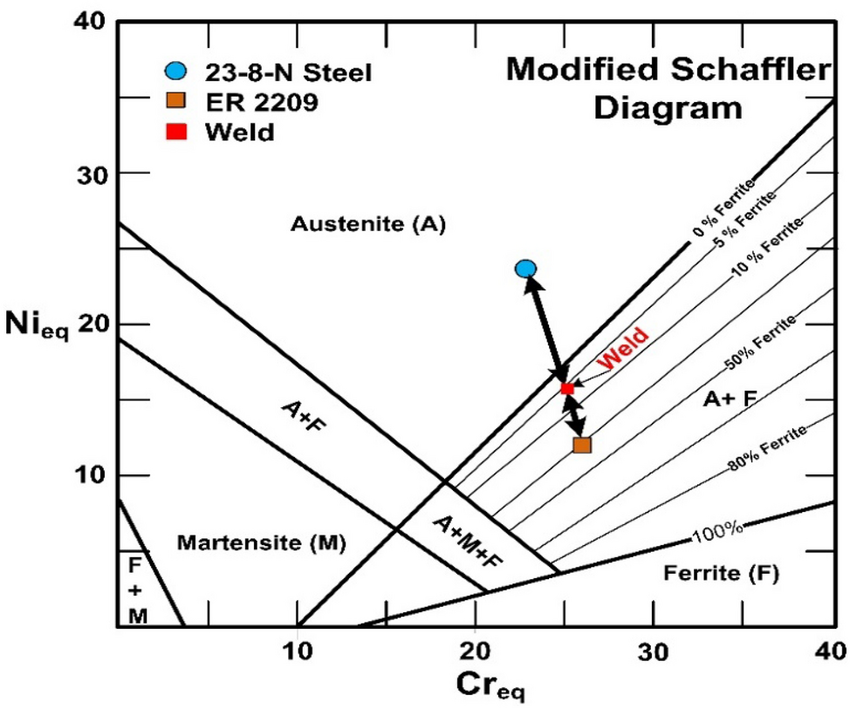

So, what exactly is this Schaeffler diagram? Think of it as a map for welders, developed by Carl Schaeffler back in the day. It helps us predict the microstructure of a weld metal based on the chemical composition of the base and filler metals. By plotting the amounts of elements like chromium, nickel, and carbon, we can foresee whether our weld will be austenitic, martensitic, or ferritic. Pretty neat, right?

Now, why do we need this diagram? Well, knowing the microstructure is crucial because it affects the weld's mechanical properties and corrosion resistance. The last thing we want is a brittle weld that could crack under stress or corrode prematurely. With the Schaeffler diagram, we can make informed choices to ensure our welds are strong, durable, and fit for purpose.

In a nutshell, the Schaeffler diagram is like having a trusty roadmap in the complex world of metallurgy. It takes the guesswork out of welding stainless steels and helps us deliver top-notch results every time. So next time you're prepping for a project, give this diagram a look—it might just make your life a whole lot easier!

Here is a calculator that I have been using for free for years. You can choose from 3 different methods. via- migal.co

- Schaeffler diagram with different base materials

- Schaeffler diagram without filler metal

- Schaeffler diagram for standard analysis

Discussion