Space-Made Aluminum Weld Analyzed

Strict followers of the this blog will remember my ThinkOrbital story last month. Now it's time to analyze the first autonomous welding in orbit.

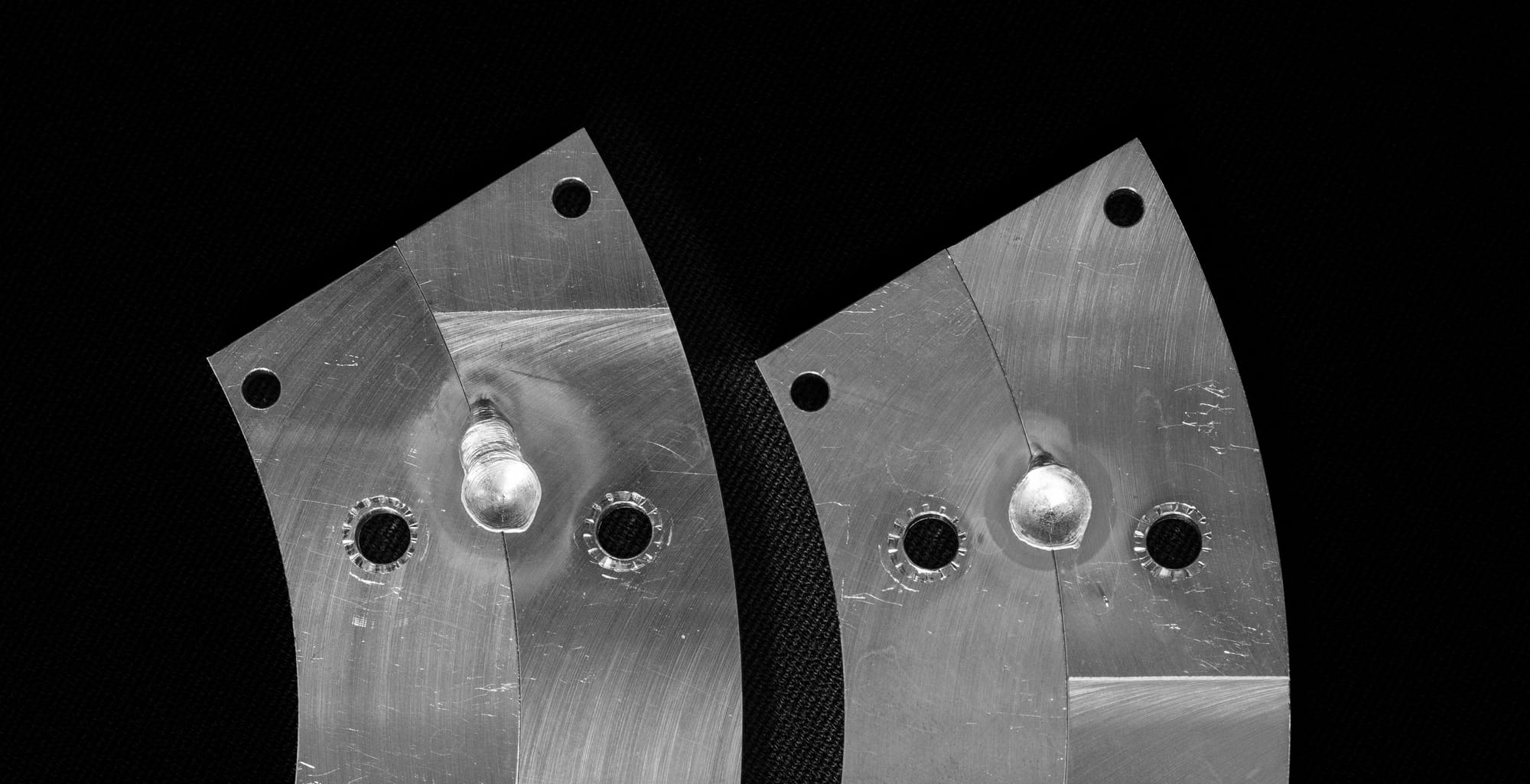

The European Space Agency (ESA) has analyzed the first autonomous weld performed in space using advanced microscopy, hardness testing, and X-ray tomography at their Netherlands laboratory. This weld, made from aerospace-grade aluminum, is crucial for developing in-space manufacturing capabilities. João Gandra, an ESA Materials Engineer, highlighted that space welding differs due to microgravity, radiation, and vacuum conditions, making it essential to gather empirical data. The weld was produced by an electron beam welding gun flown aboard a SpaceX Falcon 9, marking a milestone in sustainable space construction efforts.

Strict followers of the this blog will remember my ThinkOrbital story last month. 👇

Historically, space welding dates back to the USSR's Soyuz-6 in 1969 and later space stations, but no orbital welds were performed for four decades until this recent experiment. The electron beam welding method, which suits the vacuum of space, proved highly efficient for deep metal penetration without energy waste. ThinkOrbital, which initiated the experiment, collaborated with ESA and NASA, aiming to expand humanity’s capabilities for long-term space exploration and construction.

ThinkOrbital CEO Colonel Lee Rosen emphasized the experiment's significance in advancing space technology. ESA's João Gandra added that the initiative aligns with ESA’s strategy to advance in-space manufacturing, an essential component for future missions beyond Earth. The ESA team will continue analyzing the weld samples, contributing to the development of technologies for space economy and sustainable exploration.

Source:

Discussion