Simple Tips to Tackle Stick Welding Arc Blow

Like many of you, I’m also an avid follower of the weld.com YouTube channel. They wrapped up 2024 with another fantastic topic, and I wanted to summarize their video for you in the famous "What is arc blow?"

Understanding and Addressing Stick Welding Arc Blow

If you’re a welding professional or a student just starting out, chances are you’ve encountered the frustrating phenomenon known as arc blow. It’s not your skill or your machine to blame—this is all about magnetic interference. Arc blow causes the welding arc to deviate unpredictably, leading to spatter, messy welds, and wasted time. Here’s a closer look at what arc blow is and three essential strategies to control it effectively.

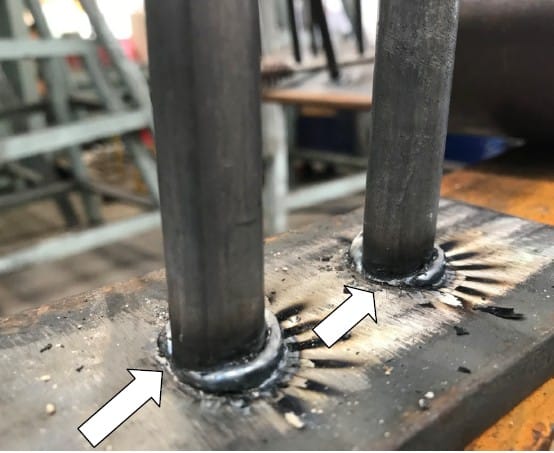

Arc blow occurs due to magnetic fields forming within the metal during welding. When you’re using stick welding (SMAW), these magnetic fields can become uneven, especially near the end of a weld plate or where grounding points are fixed. This can push the arc away from your intended weld path, making it difficult to maintain clean, consistent welds.

Three Key Tips to Minimize Arc Blow

1. Adjust Your Ground Location

The position of your ground clamp significantly affects magnetic field distribution. Experiment with moving the ground clamp to different locations on the weld piece to balance the magnetic forces. Welding toward or away from the ground can also help you regain control over the arc.

2. Change Your Welding Direction

If you notice arc blow occurring mid-weld, stop immediately and assess the situation. Switching the direction of your weld can often reduce the uneven magnetic field effects. For instance, if you’re working on a 2G weld, alternating weld directions can help neutralize arc blow.

3. Shorten Your Arc Length

A shorter arc length reduces the distance that the magnetic field can influence. By holding the electrode closer to the weld surface, you create a more focused arc that is less likely to wander. This simple adjustment can make a significant difference in controlling the weld path.

Discussion