NASA wants to use CMT welding on the Moon

Last fall, NASA's Marshall Space Flight Center concluded a project that investigated a 3D-printing (or additive manufacturing) technique that could build lunar infrastructure from aluminum potentially extracted from dust and rocks on the Moon.

A new project aims to develop the use of Cold Metal Transfer (CMT) & Wire Arc Additive Manufacturing (WAAM) with aluminum alloys for lunar infrastructure.

Aluminum's importance in lunar regolith (the layer of unconsolidated solid material covering the bedrock of a planet) and industrial applications makes it a key material for building on the moon.

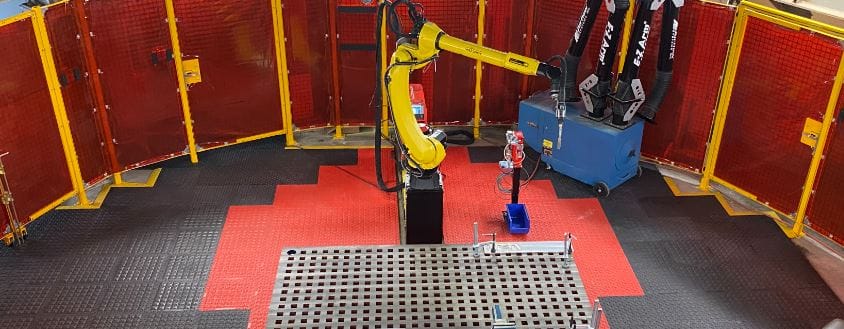

The year-long project focused on developing stable processes, complex geometries, and evaluating vacuum welding environments. Unlike powder-based methods, CMT-WAAM is safer and doesn't require special containment, making it a valuable technology for lunar manufacturing.

This initiative focuses on developing stable processes, complex geometries, and vacuum-based manufacturing, which are crucial for scaling up the technology. The project directly addresses NASA's identified gaps in large-scale additive manufacturing, on-orbit repair, and lunar surface fabrication.

Discussion