How Preheated Shielding Gas Impacts GTAW Welding Performance

I came across an impressive article, and it says: Preheating shielding gas can transform GTAW welding, improving stability, reducing penetration, and cutting gas costs—ideal for precision applications.

If you’ve ever dabbled in gas tungsten arc welding (GTAW), you know how much the choice of shielding gas can influence your welds. But what if I told you that preheating the shielding gas could have a significant effect on the welding process? A recent study explored just that, diving into how heating up your gas before it hits the arc can change the welding dynamics, and the results are pretty intriguing.

This study's title is: The Effects of Preheating the Shielding Gas Used in Gas Tungsten Arc Welding

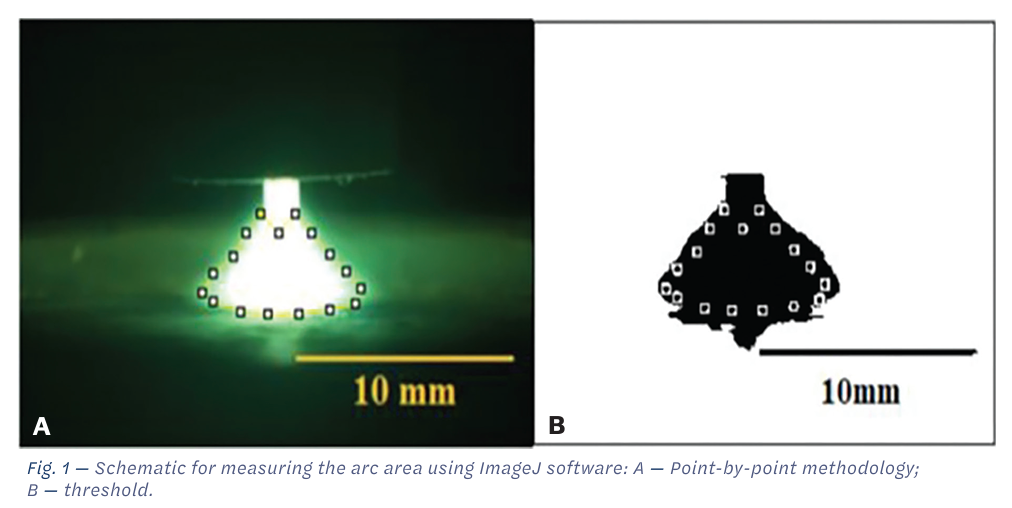

The research focused on understanding the impact of preheating the shielding gas on variables like welding voltage, heat input, and the arc’s profile. The findings were clear: heating the shielding gas affects the arc's behavior, leading to changes in weld geometry—most notably, increasing the weld width while reducing penetration. This kind of adjustment can be a game-changer for welders working with thin plates or in scenarios where precise heat control is key, such as micro TIG welding. Moreover, the study highlighted how preheated gas allowed for stable welding at lower currents (10–70 A), which is ideal for delicate welding applications.

Another interesting outcome from the research was the potential to reduce shielding gas flow while still achieving high-quality welds. That means cost savings without compromising on the weld quality—a definite plus for anyone looking to make their operation more efficient. The expanded arc and increased light emission noted in the study suggest that preheating could be a practical step forward for those needing a stable arc and controlled heat input, particularly in specialized applications where every detail counts.

If you want to read the article in detail, you can download the PDF file below or find it on AWS's own page.

Discussion