Cold Welding: A Game-Changer for Spacecraft Repairs

I recently stumbled upon an intriguing development in the world of welding that has taken innovation to new heights—literally. A groundbreaking research project is testing the potential of cold welding for in-orbit spacecraft repairs.

I previously told you about the laser and electron beam welding experiments conducted in space.This time, we need to start a new chapter for cold welding.

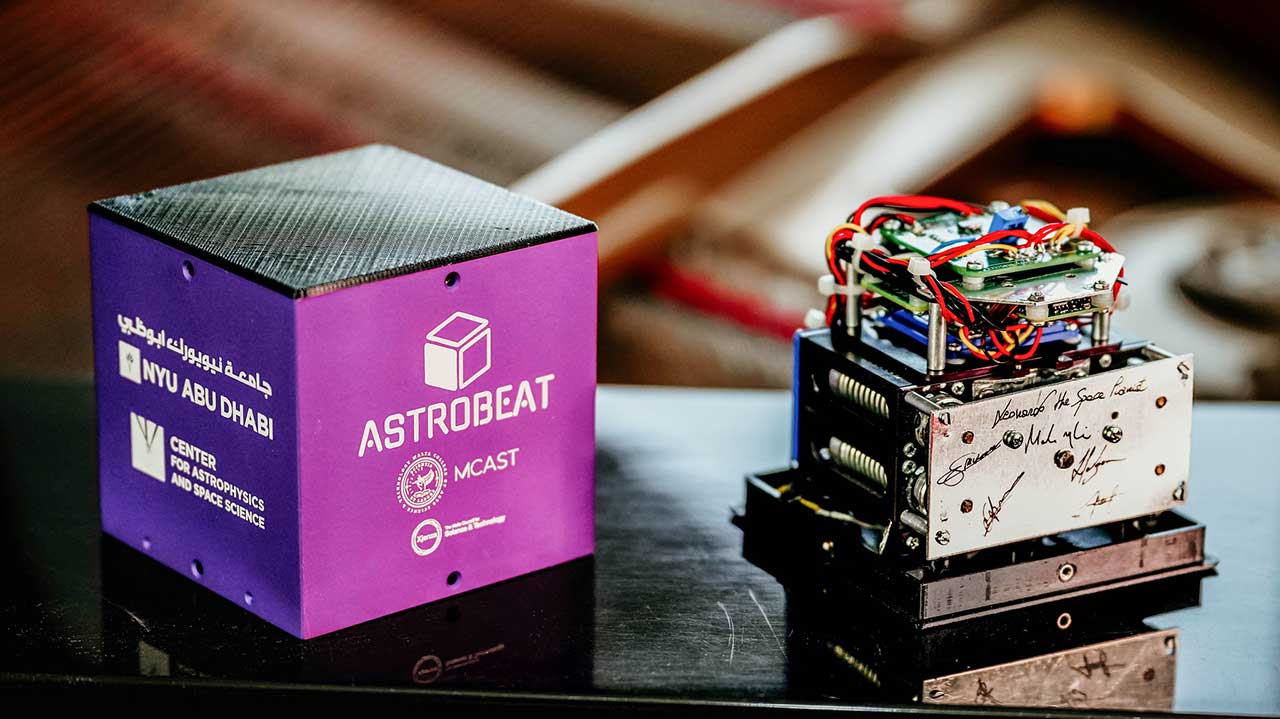

The experiment, part of the Astrobeat initiative, recently made its way to the International Space Station (ISS) aboard SpaceX’s 31st Commercial Resupply Services mission for NASA.

Cold welding, which joins metals without heat by using calibrated force, could revolutionize how we handle hull breaches caused by micrometeoroids or space debris. Unlike traditional repair methods, cold welding eliminates the risks associated with high-temperature techniques that could compromise the structural integrity of spacecraft. The space station’s microgravity environment offers the perfect conditions for this, as metals remain clean and oxide-free, resulting in stronger, more reliable bonds.

The initiative, led by Dr. Leonardo Barilaro, aims to evaluate this method on simulated spacecraft hulls. If successful, it could empower astronauts to quickly and efficiently repair damage from inside the spacecraft, enhancing both safety and mission longevity. Transforming what was once seen as a problem—cold welding’s unintentional bonding of materials in space—into a cutting-edge solution, Astrobeat is pushing the boundaries of what welding can achieve. For those of us in the welding community, this is a thrilling glimpse into how our craft continues to adapt and innovate in extraordinary settings.

While browsing YouTube, I came across the following cold welding experiment. An interesting content simulated in a laboratory environment.

Source:

Discussion