Cobots and Spot Welding: A Smarter Future for Fabrication

I wanted to share an article that was just published in FAB Shop Magazine Direct, about the combination of cobots and spot welding.

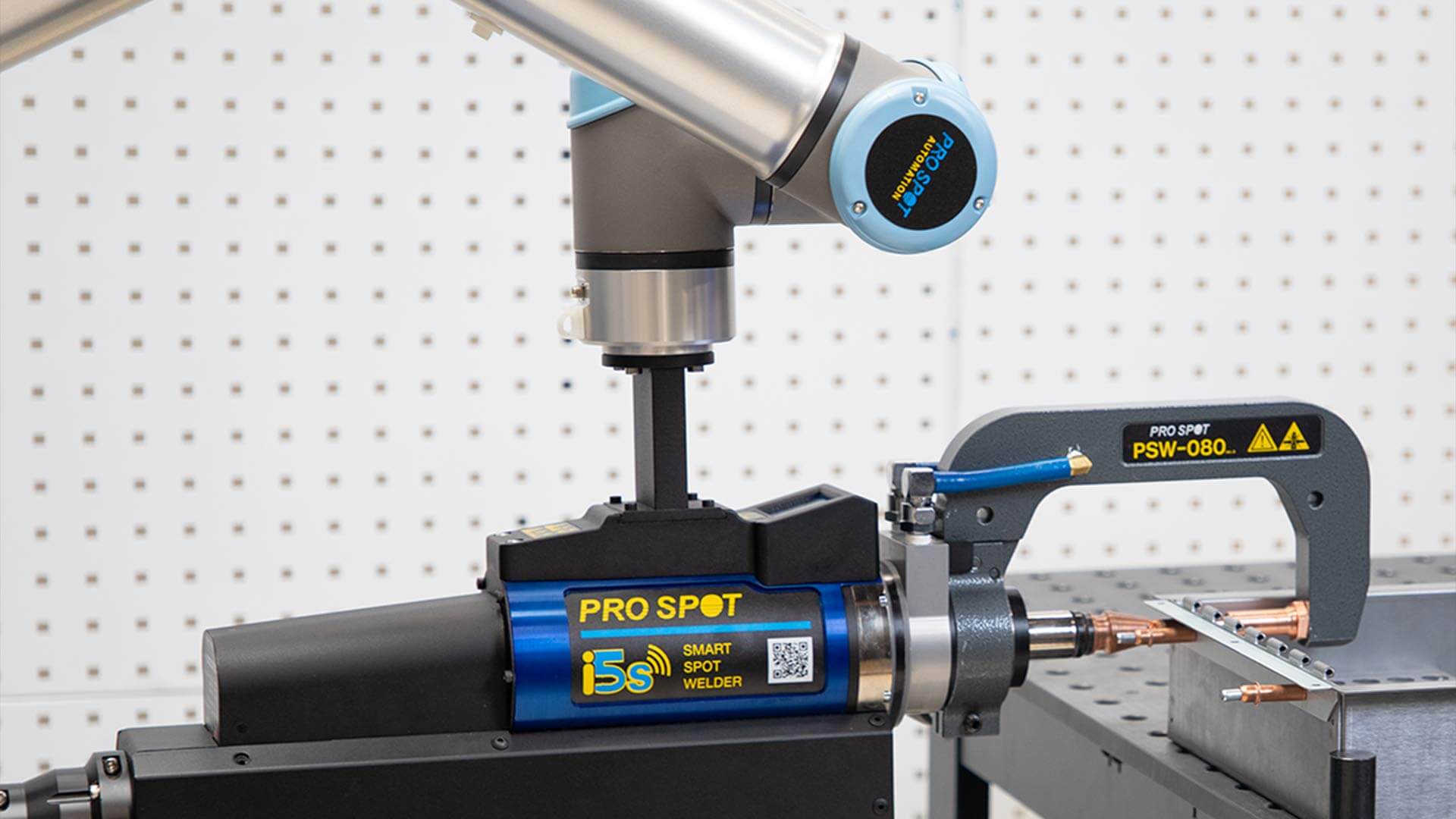

Pro Spot International Inc., a company that started with a focus on automotive collision repair, has developed cobot-assisted spot welding systems that are turning heads. By integrating Universal Robots’ cobots with their Auto Weld technology, Pro Spot offers a solution that streamlines the welding process while maintaining consistency and speed. These systems can identify material type, thickness, and layers, ensuring optimal welds every time. For operators, this means less physical strain and higher productivity—an appealing prospect in an industry often grappling with skilled labor shortages.

One standout application is at Lewis Welding Inc., where Pro Spot’s cobot system delivered a 40% increase in production throughput, reducing an eight-hour job to just 2.5 hours. Beyond efficiency, the cobots provide unmatched safety features, such as automatic stops upon contact, and simplify setup so that even less-experienced operators can start welding with ease.

Looking ahead, it’s clear this marriage of cobots and spot welding will only grow stronger. Whether it’s fabricating steel components or developing smarter repair shop solutions, the benefits of these advanced systems are undeniable. For any welding shop aiming to stay competitive, adopting this level of automation isn’t just a choice—it’s the future.

Source:

Discussion