AI and Advanced Welding: Revolutionizing Automotive Manufacturing

I came across an article this week that highlights exciting advancements in automotive manufacturing, particularly in welding technology. The article examines how engineering and artificial intelligence (AI) are transforming the welding process, crucial for both traditional cars and electric vehicles (EVs). As vehicles evolve, so too do the techniques required to ensure structural integrity and safety, especially when dealing with the complex battery systems in EVs.

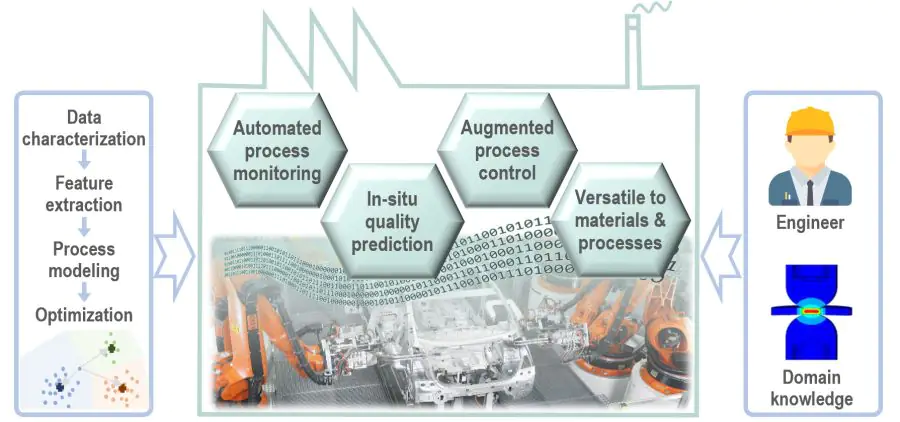

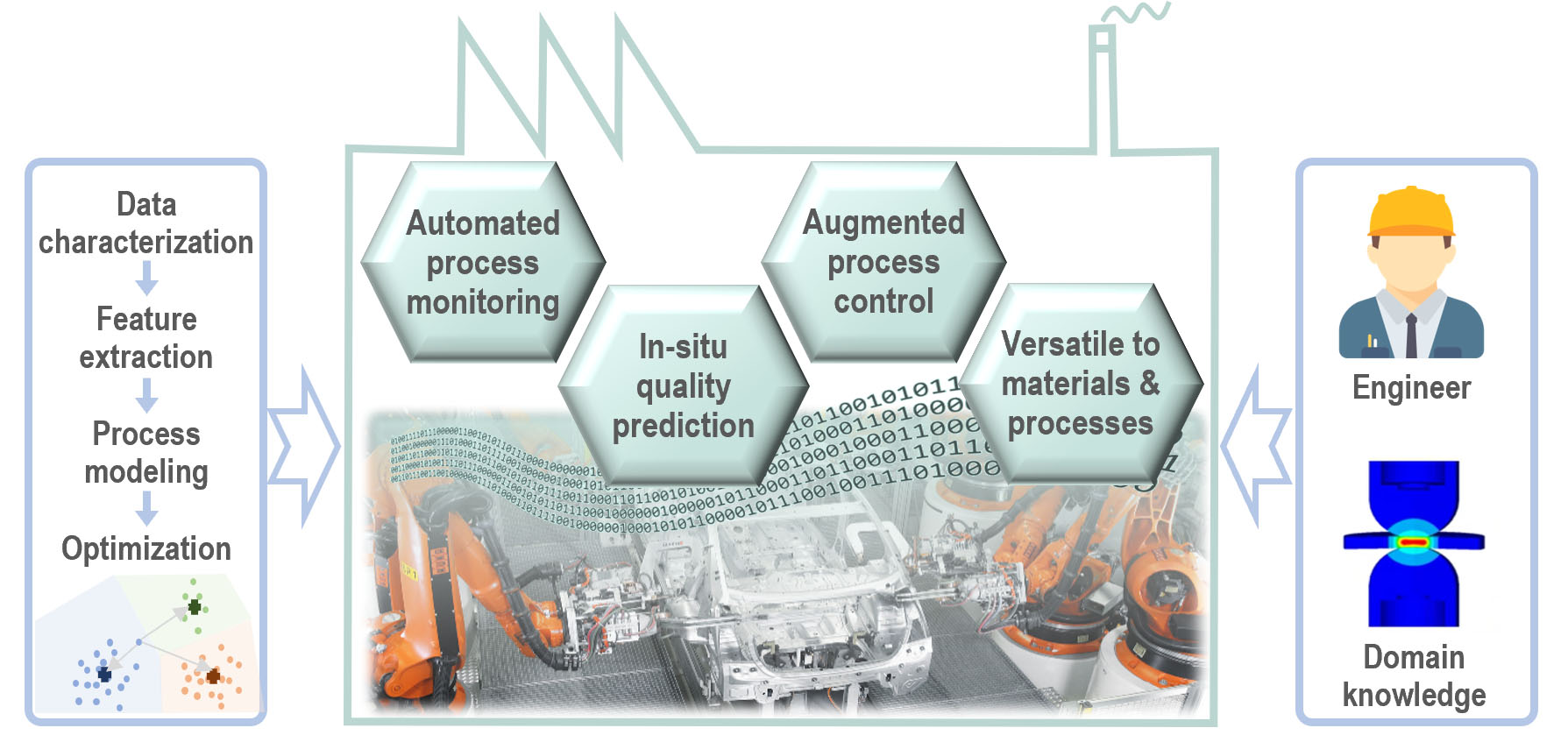

The article explores how welding engineers, armed with advanced process sensing tools and AI-driven algorithms, are pushing the boundaries of quality control. AI and machine learning (ML) are now playing a key role in detecting defects and predicting weld quality in real-time, automating what was once a manual, labor-intensive process. This evolution is helping manufacturers maintain high standards while increasing efficiency.

Looking ahead, the future of intelligent welding includes greater automation, adaptability across materials and welding processes, and close collaboration between AI systems and human experts. These innovations will shape the next generation of vehicle manufacturing, ensuring both traditional and electric vehicles are built to meet rigorous safety and performance standards.

You can access the full article from this link;

And lastly, if you want to browse more content about AI, you can also check the AI tag on the homepage.

Discussion