Advancing Laser Welding: Fuel Cell Production Speeds Boosted

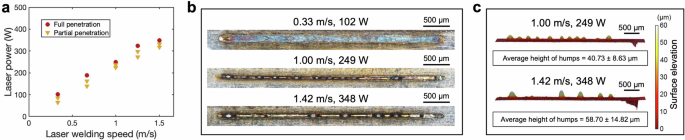

Fuel cells, known for their emission-free energy production, rely heavily on precision in creating their bipolar plates. These plates are crucial for channeling energy, but their production has long been limited by welding speed due to a pesky defect called “humping.”

A research team at Penn State has tackled this challenge head-on. By combining high-speed X-ray imaging and analytical modeling, they identified the root causes of humping and devised a method to mitigate it. Their breakthrough allows welding speeds to increase from 20 meters per minute to an impressive 75 meters per minute without surface irregularities. This jump in efficiency means production could now reach up to 80,000 fuel cells annually, a critical step for the automotive sector.

The solution involved stabilizing molten metal pools, a key contributor to humping at high speeds. Using shielding gases and adjusting the laser beam’s shape, the researchers fine-tuned welding parameters to create smooth seams even under rapid conditions. This demonstrates how fundamental research can resolve real-world manufacturing bottlenecks.

This progress doesn’t just boost production—it challenges traditional perceptions of industrial engineering. It showcases how blending hands-on techniques with cutting-edge research can create impactful solutions for clean energy technologies.

Source:

Discussion